fasteners

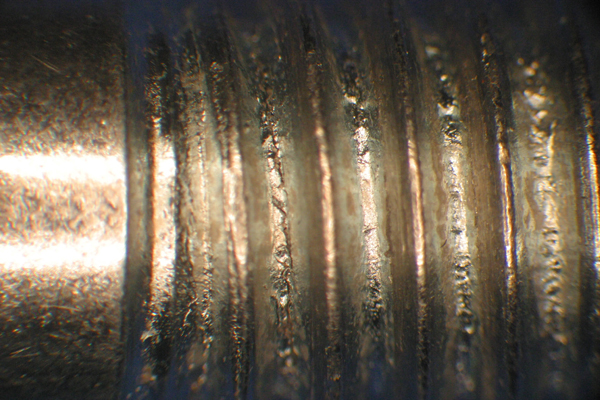

Fasteners are the glue that holds your components together. Knowing if they are designed to PERFORM is key.

You depend on your components to withstand the rigors of the jobs you ask them to perform. Fasteners need to be designed to carry working loads and not corrode over time. If their chemical makeup or condition is not at the right specification, failure could occur. Failures in your business could mean delays or serious safety concerns. MES has an experienced engineering team that has the materials knowledge necessary to help you mitigate potential problems early, achieve regulatory approvals, extend service life, reduce operating costs and minimize the need for replacements.

TESTING CAPABILITIES:

Chemical analysis lets you quickly understand the chemistry of your fastener. Understanding the material makeup is necessary in identifying potential problems or determining why a fastener failed. MES can help verify an alloy composition, coating thickness, or coating composition.

Mechanical testing shows you how well your fastener will perform under stress, which includes wear and tear, as well as various load profiles. Knowing these factors is critical for your success in a manufacturing or development environment.

Corrosion testing determines how your components and parts will perform when exposed to environmental conditions that cause them to breakdown. We offer salt fog testing, CASS testing, immersion testing, and cyclic corrosion exposure. Our corrosion testing labs are able to analyze the results in a controlled environment and at an accelerated rate, which saves you time.

Learn more about our testing capabilities.